Chris Levitt Profile

Seniors Chris Levitt and Duncan McKee pose in front of their work.

This past summer senior Chris Levitt went to a summer camp called Operation Catapult. The camp, which is hosted by Rose Hulman University in Indiana, took place over three weeks. During this time, students interested in engineering worked on completing science projects which were conducted in groups. As they settled in, students decided upon their projects and started to prepare.

“Within the first few days of camp we were talking to the professors about what we could do for our projects, which is more or less the whole purpose of the camp,” Levitt said. “We were talking to the chemical engineering professor and the bioengineering professor, and we came up with this idea of propagating this lipid-producing algae, basically oil-producing algae. We planned on extracting this oil for fuel.”

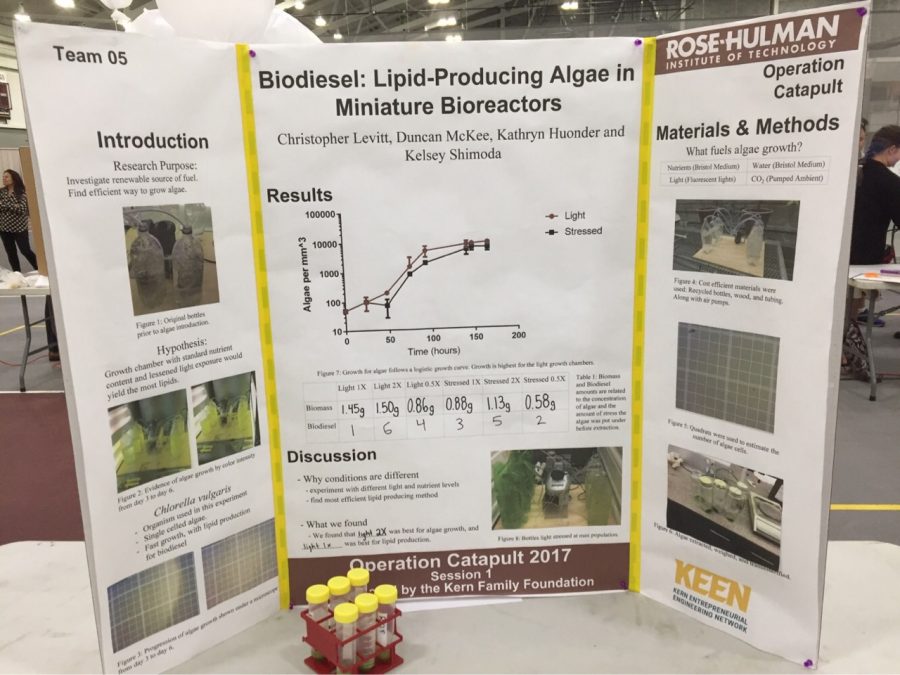

After deciding upon their project, Levitt’s group started to gather supplies.The supplies list was as follows: roughly one square yard piece of plywood, six plastic 2-liter bottles, an air pump, some plastic tubing, fluorescent lights which were found in the greenhouse, algae which was supplied by the professor and green cellophane as a light filter. While completing the project, Levitt’s group faced restrictions which made collecting the supplies more difficult.

“We were given a budget of $60 which is very easy to blow on a science experiment so we relied on salvaging anything we could,” Levitt said. “We found an air mattress pump which we attached to some plastic tubing to split into different containers of the bioreactor because we needed to pump air into the water for the algae, but the air mattress pump blew up after the 4th continuous day of running so we had to buy a real air pump. It took us an entire day of wandering around campus to find six emptied two-liter soda bottles, which was surprising considering we were on a college campus.”

After gathering materials, the project was conducted during the two weeks remaining.

“There was this algae called Chlorella vulgaris which under certain conditions produces a kind of oil that can be chemically refined into biodiesel which is just a friendlier name for diesel,” Levitt said. “We had to design the bioreactor ourselves and we decided to test different factors of growth to determine which would have the largest oil yield. We wanted to determine what would have the best lipid yield so we tested six different conditions. Three of our containers were filtered by green light at the end of the growth period in order to stress the algae because they can’t absorb the green light and use it to photosynthesize. But they produce more oil when they are under the stressed conditions as a kind of backup metabolite. Then the other three were not filtered by green light at the end and we also had three separate concentrations of our food for the algae, one of each for the green light. We basically tracked the population growth and at the end extracted all the algae and all the oil we got from the algae and compared the results.”

The findings of the experiment were that the conditions imposed upon the algae had significant effects on what was produced in terms of algae amount and oil.

“We found the one with the second highest oil yield had the lowest population yield but because it had half the concentration of food and it was stressed with the green light, it produced more oil than most of the rest,” Levitt said. The reason that’s a significant finding is because if you were to produce biodiesel on an industrial scale you would want to do it in the most cost-effective way. Although this setup didn’t yield the most of the six, it yielded the 2nd most and used the fewest materials which made it a viable option for production.”

Your donation will support the student journalists of Bellaire High School. Your contribution will allow us to purchase equipment and cover our annual website hosting costs.